BLR TUNING

RykerMod Super Billet SWAY BAR End Links For CAN-AM RYKER

RykerMod Super Billet SWAY BAR End Links For CAN-AM RYKER

Couldn't load pickup availability

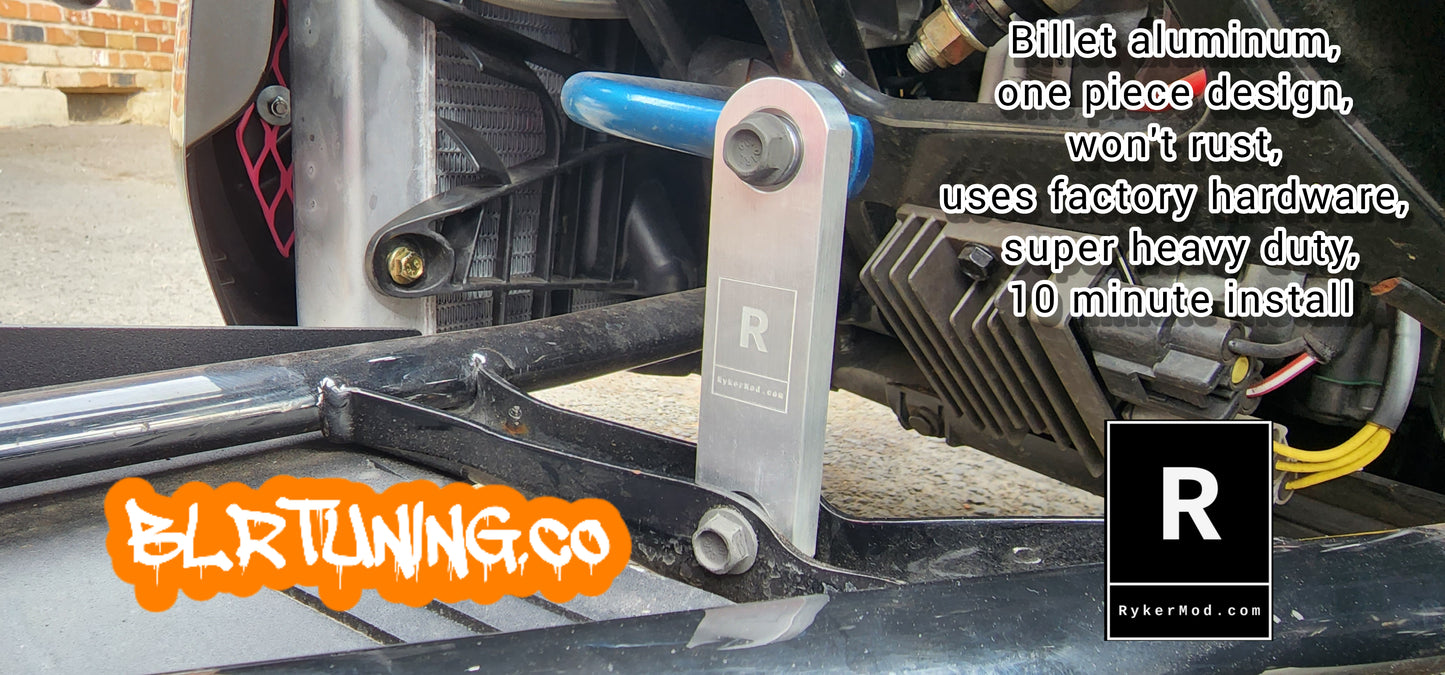

CAN-AM RYKER SUPER BILLET SWAY BAR END LINKS BY RykerMod.

NOW ALSO AVAILABLE IN ANODIZED BLACK

HEAVY DUTY, PRECISE OEM FIT, BILLET ALUMINUM, USES FACTORY HARDWARE, WILL NOT RUST, TEN MINUTE INSTALL

FITS ALL YEARS AND ALL MODELS OF CAN-AM RYKER. 19-23 RALLY, 600, 900, SPORT

SHIPPING ANYWHERE IN THE US IS INCLUDED AT NO EXTRA CHARGE

THIS WILL DRASTICALLY IMPROVE THE HANDLING AND STABILITY OF YOUR RYKER. THIS WILL HELP PREVENT BODY ROLL WHEN GOING INTO A CORNER. IT WILL ALSO HELP KEEP THE BIKE TRACKING STRAIGHT WHEN YOU'RE GOING DOWN THE FREEWAY. THIS IS BY FAR ONE OF THE FIRST MODIFICATIONS YOU SHOULD CONSIDER WHEN PURCHASING A CAN-AM RYKER.

WITH THIS NEW ONE PIECE BILLET ALUMINUM DESIGN AND THE HEAVY DUTY BEARINGS THESE WILL OUTLAST THE LIFE OF YOUR VEHICLE. HEAVIER DUTY THAN ANY OTHER SET OF SWAY BAR END LINKS ON THE MARKET.

What Makes Us Different ?

1. Our End Links are engineering to be precision and installed without spacers... We manufacture Chrome Molly inserts for proper mating surface load transfer.

We do not incorporate spacers or stacked washers for your end links. Rigid connections are paramount for proper suspension dynamics.

2. We do not make our End Links adjustable... Why?

Suspension Geometry for Rykers is fixed, so changing the length of the rod ends are of no benefit and in most cases. If one side is adjusted slightly longer than the other it may cause premature failure of some components. .

3. Increased Bearing Size. Made with SKF Spherical bearings.

We use COM5 (8mm) bearing, All other manufactures use GE6 (6mm) bearing sizes, Why did we make this change?

Static load, Our bearings are 20% stronger

Doing so allows us to install chrome molly inserts

4. We Make our End Links to exact factory specs to maintain proper geometry.

We use anodized 6061 T6 Aluminum

Center distance from bearing to bearing center is correct to factory specs.

We do not cut away the sides of the link for a design feature, as to take full advantage of the bearing and material load capabilities.

A QR CODE IS INCLUDE THAT WILL TAKE YOU TO THE YOUTUBE INSTALLATION VIDEO - https://www.youtube.com/watch?v=VYM_7epAIu0&t=2s

Existing Hardware to be used. Torque specs for the locking nuts is 89 in pounds. There is no need to use loctite.

Share